Loading.....

IoT and Robotics Interaction Shaping the Future of Industry 4.0

In the bustling heart of today's industries, the convergence of IoT (Internet of Things) and Robotics stands as a testament to the transformative power of technology. This symbiotic relationship between IoT and Robotics is not merely a trend but a cornerstone of the industrial revolution. Let's delve deeper into this synergy and learn more about how IoT and robotics are together transforming Industry 4.0.

The Relationship Between IoT & Robotics

At first glance, IoT and Robotics may seem like distinct entities with separate functionalities. However, their interaction is where the magic happens.Internet of Things (IoT) serves as the nervous system, connecting robotic systems with the digital world. Through a network of sensors, actuators, and communication protocols, IoT enables robots to gather and exchange data in real-time, facilitating seamless integration and coordination within industrial environments.

This connectivity empowers robotics with enhanced perception, cognition, and decision-making capabilities. Robots equipped with IoT sensors can collect valuable data on operational parameters, environmental conditions, and performance metrics. This data, in turn, fuels insights-driven optimization, predictive maintenance, and adaptive control, leading to improved productivity and resource utilization.

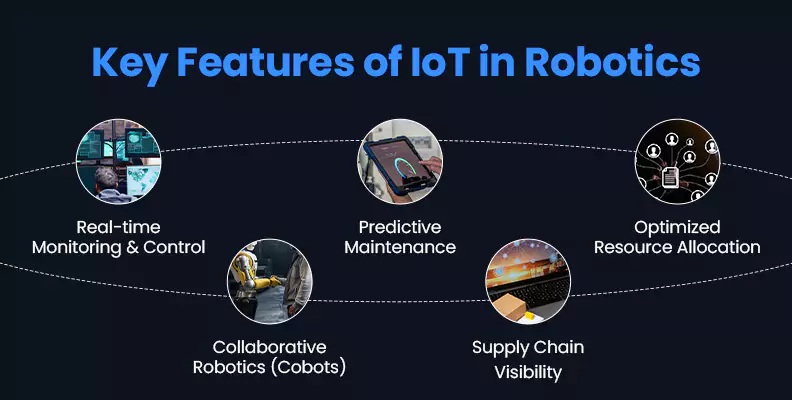

Key Features of IoT in Robotics

- Real-time Monitoring and Control: IoT enables remote monitoring and control of robotic systems, allowing operators to oversee operations, diagnose issues, and make adjustments in real-time, irrespective of geographical constraints.

- Predictive Maintenance: By leveraging IoT sensors to monitor equipment health and performance, predictive maintenance algorithms can anticipate potential failures, schedule timely interventions, and prevent costly downtimes.

- Optimized Resource Allocation: IoT-powered analytics provide actionable insights into resource utilization, energy consumption, and workflow efficiency, enabling organizations to optimize processes, minimize waste, and drive cost savings.

- Collaborative Robotics (Cobots): IoT facilitates seamless collaboration between humans and robots, fostering safer work environments and enhancing productivity through shared tasks and adaptive workflows.

- Supply Chain Visibility: Through IoT-enabled tracking and tracing, robotics systems can provide end-to-end visibility across the supply chain, from raw material sourcing to product delivery, enabling faster response times and improved inventory management.

The Advanced Features of IoTR

The integration of IoT in Robotics unlocks a plethora of advanced features that further enhance operational efficiency and drive innovation:

- Edge Computing: IoTR leverages edge computing capabilities to process data closer to the source, reducing latency and enabling real-time decision-making at the edge of the network.

- Autonomous Navigation: IoT-enabled robots can navigate complex environments autonomously, leveraging data from sensors and IoT networks to avoid obstacles, optimize paths, and adapt to dynamic conditions.

- Human-Machine Interaction: IoTR facilitates natural and intuitive human-machine interaction, enabling users to interact with robots through voice commands, gestures, and augmented reality interfaces.

- Remote Maintenance and Diagnostics: IoT sensors enable remote monitoring of robotic systems, allowing for proactive maintenance, troubleshooting, and software updates without the need for onsite intervention.

- Data-driven Insights: By harnessing IoT data analytics, organizations can gain actionable insights into operational performance, customer preferences, and market trends, driving informed decision-making and continuous improvement.

Power of IoT and Robotics Interaction

When IoT and robotics join forces, the possibilities are limitless. IoT sensors embedded within robotic systems enable seamless communication and data exchange, empowering robots with cognitive capabilities. These interconnected systems can collect vast amounts of data from various sources, analyze it in real-time, and adapt their actions accordingly. This synergy enhances operational efficiency, optimizes resource utilization, and facilitates predictive maintenance, thereby minimizing downtime and maximizing productivity.

Benefits

- Enhanced Automation: By integrating IoT sensors into robotic systems, industries can achieve a higher degree of automation, streamlining repetitive tasks and minimizing human intervention. This not only increases operational efficiency but also reduces labor costs and enhances workplace safety.

- Data-Driven Decision-Making: The amalgamation of IoT and robotics generates a wealth of data pertaining to production processes, equipment performance, and environmental conditions. Leveraging advanced analytics, industries can derive actionable insights from this data, enabling informed decision-making and proactive problem-solving.

- Optimized Supply Chain Management: IoT-enabled robotics facilitates end-to-end visibility across the supply chain, from inventory management to logistics and distribution. By tracking assets in real-time and predicting demand fluctuations, companies can optimize inventory levels, minimize stockouts, and improve order fulfillment efficiency.

- Quality Assurance: Robotics equipped with IoT sensors can monitor product quality throughout the production process, detecting defects or deviations from specifications in real-time. This proactive approach to quality assurance ensures that only products meeting the highest standards reach the market, enhancing customer satisfaction and brand reputation.

Industry Applications of IoT in Robotics

The applications of IoT in robotics span across various industries, each reaping the benefits of this powerful alliance:

- Manufacturing: In smart manufacturing factories , IoT-enabled robots collaborate seamlessly with human workers, optimizing production lines, monitoring equipment health, and facilitating predictive maintenance. Real-time data from IoT sensors empower robots to adapt to changing conditions and perform tasks with unparalleled efficiency.

- Logistics and Warehousing: IoT-equipped robots streamline warehouse operations by autonomously managing inventory, picking and packing orders, and navigating through complex environments. This not only accelerates order fulfillment but also minimizes errors and reduces operational costs.

- Healthcare : Robotics augmented with IoT sensors revolutionize patient care by assisting in surgeries, monitoring vital signs, and providing remote assistance to healthcare professionals. This integration enhances precision, reduces risks, and improves patient outcomes in medical procedures.

- Agriculture: IoT-driven robotics automate agricultural tasks such as planting, harvesting, and monitoring crop health. By analyzing data from soil sensors, drones, and weather stations, these robots optimize resource usage, increase crop yields, and promote sustainable farming practices.

Conclusion: The Road Ahead

As we stand on the precipice of a new industrial era, the convergence of IoT and Robotics serves holds immense promise for driving innovation, unlocking new business models, and reshaping the future of industry. By harnessing the power of interconnected systems, organizations can gain a competitive edge in an increasingly digitized and automated world.

In conclusion, the symbiotic relationship between IoT and Robotics epitomizes the transformative potential of Industry 4.0 technologies. As these technologies continue to evolve and converge, they will undoubtedly redefine the way we work, produce, and interact with machines, paving the way for a smarter, more connected future.

Back to blog

Back to blog